What is HALT?

Highly Accelerated Life Testing (HALT) techniques are important in uncovering many of the weak links inherent to the design and fabrication processes of a new product.

These discovery tests rapidly find weaknesses using accelerated stress conditions.

- Find a weakness...

- Improve the weakness...

- Find another weakness…

- Improve that weakness…

- Continue until there are no identifiable weaknesses that could cause field failures or remaining weaknesses are not cost-effective to resolve

The HALT Process

HALT is a method aimed at discovering and then improving weak links in a product during the design phase. HALT is a discovery test as opposed to a compliance test; that is, the goal is to find problems, doing everything necessary to find and then remove the weaknesses.

In HALT, every stimulus of potential value (temperature, all-axis vibration, humidity, UV, radiation, etc.) can be used under accelerated test conditions during the development phase of a product to find the weak links in the design and fabrication processes. Accelerated stresses in combination (e.g. high-temperature ramp rates and all-axis vibration levels together) are necessary to compress or minimize the time to failure.

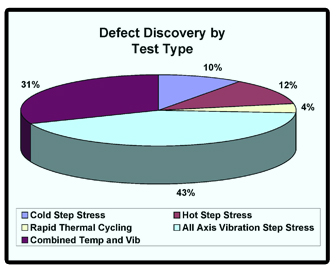

The chart below shows where design flaws were discovered during the HALT process and why all-axis vibration is important.*

* Chuck Laurenson, Parker Hannifin

Therefore, 74% of the flaws would have been missed without simultaneous, all axis vibration

By stressing the product beyond its design specification, operational and destruct limits can be determined, and decisions can be made on how to increase these margins. Each weak link provides an opportunity to improve the design or the processes, which will lead to reduced design time, increased reliability, and decreased costs. Used properly, HALT compresses this design cycle while providing a significantly more reliable and mature product at introduction. Studies have shown that a six-month advantage in product introduction can result in a lifetime profit increase of up to 50% for the market mover.

References: Accelerated Reliability Engineering, Gregg K. Hobbs, Hobbs Engineering, 2005.